|

Fastest Samples Guaranteed... Delivered in as low as 9 Days... |

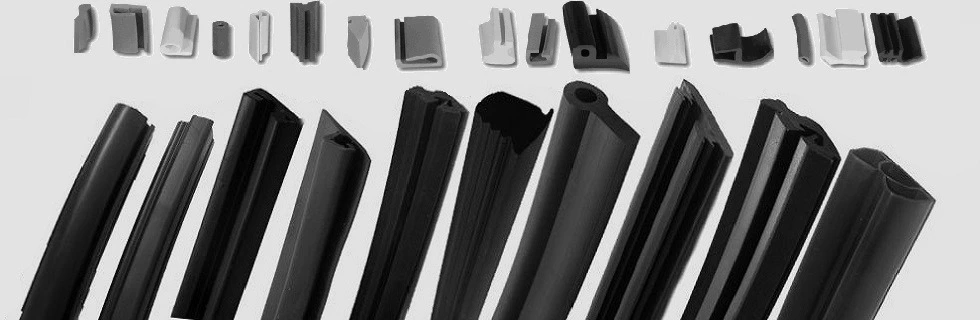

Rubber Mouldings

- Rubber Molding Companies

- Rubber Moulding

- Rubber Molding

- Rubber Trim Molding

- Rubber Base Molding

- Rubber T Molding

- Rubber Compression Molding

- Molded Rubber Parts

- Rubber Moulded Production

- Rubber Mold Company

- Silicone Rubber Mold

- Rubber Molds

- Rubber Molds For Concrete

- Rubber Moulds Manufacturers

- Rubber Mold Making

- Rubber Mold Design

Silicon Moldings

Casting Rubber Products

Custom Products

Gasket Products

Other Rubber Products

- Silicone Rubber Products

- Compression Molding

- Rubber Products

- Rubber Products Manufacturers

- Industrial Rubber Products

- Masking Rubber And Silicone

- Rubber Tube

- Rubber Tubing

- Rubber Hose

- Rubber Extrusion

- Custom Extrusion

- Rubber Mounts

- Rubber Couplings

- Rubber Roll

- Rubber To Metal Bonding

- Rubber Components Manufacturers

- Rubber Bellows

- Rubber Bushing

Polymer Molding Products

Seals Rings and Washers

Industries We Serve

Benefits with Rubber Molded Products

Quality Product

Ontime Delivery

IP Protection

Design and Engg. Support

CRM for Regular Updates

Above All -

Your PEACE OF MIND!!!

Small Silicone Molds In Bradford West Gwillimbury On, Ontario

It goes without saying that the silicone molds are used for wide varieties of purposes, both residential and industrial and by Serving Bradford West Gwillimbury On customers. We are specializes in manufacturing and supplying wide varieties of molds to cater to the needs of different customers. If you are in need of small silicone molds, you can feel free to get in touch with us because we can design the mold in the exact size that you want. Therefore, it can help in serving a great deal of purpose.

Different From Others:

We pride ourselves in the fact that we stand out from the rest of our competitors, based Serving Bradford West Gwillimbury On .

- We make use of the latest and technically advanced tools to produce molds.

- Along with producing smaller ones, we even manufacture large silicone molds.

- We can even make bespoke molds, as per the exclusive requirements of our customers.

- We always maintain high quality standards throughout our manufacturing and production process.

Reducing the Overall Time of Cycle:

A similar process is applied even for large silicone molds. By understanding the requirements of our clients, we determine the most suitable option and cater to it in the best possible way. Hence, you will be highly satisfied.

What are the Advantages of Silicone Compression Molding?

Silicone compression molding offers numerous advantages that make it an attractive choice for various industries. This versatile manufacturing process allows for the creation of complex and intricately designed parts with exceptional precision and consistency. It enables the use of a wide range of silicone materials, known for their outstanding chemical and temperature resistance, making them suitable for demanding applications. The efficiency of compression molding results in faster production rates and cost-effectiveness, suitable for both low and high-volume production runs. Moreover, this process generates minimal waste, contributing to sustainable manufacturing practices. Its ability to produce customized shapes and sizes empowers manufacturers to meet specific requirements effectively. Overall, the advantages of silicone molding position it as a reliable and versatile solution for producing high-quality silicone parts with excellent performance characteristics.

Key Principles and Techniques of Silicone Over Molding

When it comes to silicone over molding, the success of the manufacturing process hinges on several key principles and techniques. Proper adhesion and bonding between the substrate and silicone material are paramount, necessitating thorough surface preparation of the substrate. Techniques like cleaning, priming, and surface activation are employed to enhance the adhesion strength and overall quality of the final product. Injection molding is a widely used technique in over molding, involving the injection of silicone material into a mold containing the substrate. The mold design and material selection are critical in achieving uniformity and preventing defects. Careful control of molding parameters, including temperature, pressure, and curing time, is vital to ensure consistent and reliable over-molded components. Mastering these principles and techniques is fundamental to achieving successful and high-quality results in silicone molding for various industrial applications.

If you are in search of top-notch silicone over or compression molding services, look no further than Rubber Molded Products. Our company takes pride in providing comprehensive solutions to meet all your molding requirements. With a wealth of experience and technical expertise, we specialize in offering high-quality silicone over and compression molding services for diverse industries. Whether you need intricate over-molded components or precision compression-molded parts, we have the capabilities to deliver superior results. Our commitment to excellence, coupled with advanced technology and stringent quality control, ensures that you receive products of unmatched performance and durability. Trust us for all your silicone molding needs and experience exceptional service and reliability.

We Expertise in

Custom Molded Products

Rubber To Metal Bonding

Silicone To Metal Bonding

Injection and Compression Rubber Mouldings

Custom Bellows

Grommets

Diaphrams

Rubber Mounts

Custom Seals and Gaskets