|

Fastest Samples Guaranteed... Delivered in as low as 9 Days... |

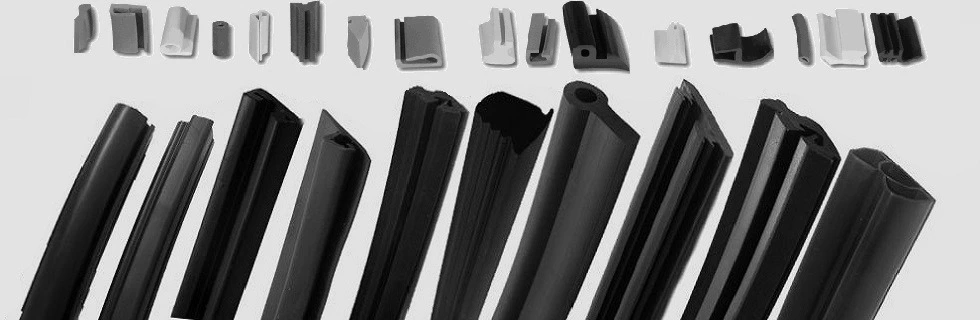

Rubber Mouldings

- Rubber Molding Companies

- Rubber Moulding

- Rubber Molding

- Rubber Trim Molding

- Rubber Base Molding

- Rubber T Molding

- Rubber Compression Molding

- Molded Rubber Parts

- Rubber Moulded Production

- Rubber Mold Company

- Silicone Rubber Mold

- Rubber Molds

- Rubber Molds For Concrete

- Rubber Moulds Manufacturers

- Rubber Mold Making

- Rubber Mold Design

Silicon Moldings

Casting Rubber Products

Custom Products

Gasket Products

Other Rubber Products

- Silicone Rubber Products

- Compression Molding

- Rubber Products

- Rubber Products Manufacturers

- Industrial Rubber Products

- Masking Rubber And Silicone

- Rubber Tube

- Rubber Tubing

- Rubber Hose

- Rubber Extrusion

- Custom Extrusion

- Rubber Mounts

- Rubber Couplings

- Rubber Roll

- Rubber To Metal Bonding

- Rubber Components Manufacturers

- Rubber Bellows

- Rubber Bushing

Polymer Molding Products

Seals Rings and Washers

Industries We Serve

Benefits with Rubber Molded Products

Quality Product

Ontime Delivery

IP Protection

Design and Engg. Support

CRM for Regular Updates

Above All -

Your PEACE OF MIND!!!

Silicone Compression Molding

With a specialization in silicone injection molding, Our Company stands at the leading position Serving Silicone Compression Molding market today. Liquid silicone has a high level of purity and when treated appropriately, it can offer great degree of stability and functionality. It can even resistant high temperature of heat and cold, and is thereby suitable for producing parts where high quality is a must. We even specialize in silicone over molding in order to suit the varied requirements of our customers in unique ways.

Quality Assured Engineering And Designing:

As one of the top silicone injection molding companies, we can always assure you of the quality engineering, designing and manufacturing Serving Silicone Compression Molding .

- We have a team of highly skilled and experienced professionals to look after the overall process of molding.

- We make use of state of the art technologies to bring out the best solutions

- We adhere to the latest industrial standards to suit the diverse requirements of our customers.

It is because of this reason that our silicone injection molding is a total success today.

Required In Various Applications:

With the best approach to the process of silicone over molding Serving Silicone Compression Molding , our products can be used in wide varieties of applications. Ranging from seals, gaskets and o rings to custom fabrication of bespoke components, airbags and others, the molds can be used in large numbers of products.

Therefore, it is time to approach one of the best silicone injection molding companies like us in order to get some of the top quality solutions. Thus, you will be satisfied.

The Role of Silicone Manufacturers in Modern Industries

What is Medical Silicone Molding and its Significance in Healthcare?

FAQ

- Q1. What Is The Process Of Silicone Injection?

Silicone injection involves injecting liquid silicone rubber into a mold cavity under high pressure. This process is used to create intricate silicone parts with consistent quality and detail. Rubber Molded Products specializes in professional silicone injection molding services for various industries.

- Q2. What Silicone Material Is Used For Injection Molding?

Silicone injection molding typically utilizes high-quality liquid silicone rubber (LSR) or high-consistency rubber (HCR) materials. These silicone materials are specifically formulated for injection molding processes, offering excellent elasticity, heat resistance, and durability. Rubber Molded Products uses top-grade silicone materials for superior product performance.

- Q3. What Temperature Is Silicone Compression Molding?

Silicone compression molding involves heating a pre-measured amount of silicone material until it reaches a specific temperature, typically between 300°F to 400°F (150°C to 200°C). The molten silicone is then placed into a heated mold cavity and compressed under pressure until it cures into the desired shape.

- Q4. What Is The Temperature Limit For Silicone?

The temperature limit for silicone varies depending on the specific type and grade of silicone used. Generally, silicone can withstand temperatures ranging from -40°F to 500°F (-40°C to 260°C). However, specialty silicone formulations can endure even higher or lower temperatures. Rubber Molded Products ensures products meet required temperature specifications.

- Q5. What Is The Compression Molding Process?

Compression molding is a manufacturing process where a preheated material, such as silicone, is placed into an open mold cavity. The mold is then closed, and pressure is applied to force the material to conform to the shape of the mold cavity. Rubber Molded Products utilizes compression molding for precision silicone part production.

We serve across following state

-

Alabama

- Birmingham AL

- Montgomery AL

- Mobile AL

- Huntsville AL

- Tuscaloosa AL

- Hoover AL

- Dothan AL

- Auburn AL

- Decatur AL

- Madison AL

- Florence AL

- Phenix City AL

- Gadsden AL

- Prattville AL

- Vestavia Hills AL

- Alabaster AL

- Opelika AL

- Enterprise AL

- Bessemer AL

- Homewood AL

- Northport AL

- Athens AL

- Daphne AL

- Pelham AL

- Anniston AL

- Prichard AL

- Albertville AL

- Oxford AL

- Mountain Brook AL

- Trussville AL

- Selma AL

- Troy AL

- Fairhope AL

- Helena AL

- Alaska

- Alberta

-

Arizona

- Phoenix AZ

- Tucson AZ

- Mesa AZ

- Chandler AZ

- Gilbert Town AZ

- Glendale AZ

- Scottsdale AZ

- Tempe AZ

- Peoria AZ

- Surprise AZ

- Yuma AZ

- Avondale AZ

- Goodyear AZ

- Flagstaff AZ

- Buckeye town AZ

- Lake Havasu City AZ

- Casa Grande AZ

- Maricopa AZ

- Sierra Vista AZ

- Oro Valley town AZ

- Prescott Valley town AZ

- Prescott AZ

- Marana town AZ

- Bullhead City AZ

- Apache Junction AZ

- El Mirage AZ

- Queen Creek town AZ

- San Luis AZ

- Kingman AZ

- Sahuarita town AZ

- Florence town AZ

- Fountain Hills town AZ

- Nogales AZ

-

Arkansas

- Little Rock AR

- Fort Smith AR

- Fayetteville AR

- Springdale AR

- Jonesboro AR

- North Little Rock AR

- Conway AR

- Rogers AR

- Pine Bluff AR

- Bentonville AR

- Hot Springs AR

- Benton AR

- Sherwood AR

- Texarkana AR

- Russellville AR

- Jacksonville AR

- Bella Vista town AR

- Paragould AR

- Cabot AR

- West Memphis AR

- Searcy AR

- Van Buren AR

- Bryant AR

- El Dorado AR

- Maumelle AR

- British Columbia

-

California

- Los Angeles CA

- San Diego CA

- San Jose CA

- San Francisco CA

- Fresno CA

- Sacramento CA

- Long Beach CA

- Oakland CA

- Bakersfield CA

- Anaheim CA

- Santa Ana CA

- Riverside CA

- Stockton CA

- Chula Vista CA

- Irvine CA

- Fremont CA

- San Bernardino CA

- Modesto CA

- Oxnard CA

- Fontana CA

- Moreno Valley CA

- Huntington Beach CA

- Glendale CA

- Santa Clarita CA

- Garden Grove CA

- Oceanside CA

- Rancho Cucamonga CA

- Santa Rosa CA

- Ontario CA

- Elk Grove CA

- Corona CA

- Lancaster CA

- Palmdale CA

- Salinas CA

- Hayward CA

- Pomona CA

- Escondido CA

- Sunnyvale CA

- Torrance CA

- Pasadena CA

- Orange CA

- Fullerton CA

- Thousand Oaks CA

- Visalia CA

- Roseville CA

- Concord CA

- Simi Valley CA

- Santa Clara CA

- Victorville CA

- Vallejo CA

- Berkeley CA

- El Monte CA

- Downey CA

- Costa Mesa CA

- Carlsbad CA

- Inglewood CA

- Fairfield CA

- San Buenaventura Ventura CA

- Temecula CA

- Antioch CA

- Richmond CA

- West Covina CA

- Murrieta CA

- Norwalk CA

- Daly City CA

- Burbank CA

- Santa Maria CA

- El Cajon CA

- San Mateo CA

- Rialto CA

- Clovis CA

- Jurupa Valley CA

- Compton CA

- Vista CA

- Mission Viejo CA

- South Gate CA

- Vacaville CA

- Carson CA

- Santa Monica CA

- San Marcos CA

- Hesperia CA

- Westminster CA

- Redding CA

- Santa Barbara CA

- San Leandro CA

- Chico CA

- Hawthorne CA

- Whittier CA

- Newport Beach CA

- Livermore CA

- Citrus Heights CA

- Tracy CA

- Indio CA

- Alhambra CA

- Menifee CA

- Chino CA

- Buena Park CA

- Hemet CA

- Redwood City CA

- Merced CA

- Lakewood CA

- Tustin CA

- Lake Forest CA

- Napa CA

- Mountain View CA

- Bellflower CA

- Pleasanton CA

- Alameda CA

- Baldwin Park CA

- Chino Hills CA

- Upland CA

- Folsom CA

- San Ramon CA

- Perris CA

- Milpitas CA

- Union City CA

- Manteca CA

- Lynwood CA

- Apple Valley town CA

- Turlock CA

- Redlands CA

- Rancho Cordova CA

- Redondo Beach CA

- Pittsburg CA

- Yorba Linda CA

- Walnut Creek CA

- South San Francisco CA

- Palo Alto CA

- Camarillo CA

- Davis CA

- Yuba City CA

- Laguna Niguel CA

- San Clemente CA

- Pico Rivera CA

- Lodi CA

- Montebello CA

- Madera CA

- Santa Cruz CA

- Encinitas CA

- La Habra CA

- Tulare CA

- Monterey Park CA

- Cupertino CA

- Gardena CA

- Rocklin CA

- National City CA

- Lake Elsinore CA

- Petaluma CA

- Huntington Park CA

- San Rafael CA

- La Mesa CA

- Arcadia CA

- Woodland CA

- Santee CA

- Brentwood CA

- Eastvale CA

- Fountain Valley CA

- Diamond Bar CA

- Porterville CA

- Paramount CA

- Hanford CA

- Novato CA

- Rosemead CA

- Dublin CA

- Highland CA

- Colton CA

- Cathedral City CA

- Watsonville CA

- Yucaipa CA

- Delano CA

- Gilroy CA

- Placentia CA

- West Sacramento CA

- Glendora CA

- Palm Desert CA

- Aliso Viejo CA

- Cerritos CA

- Poway CA

- La Mirada CA

- Rancho Santa Margarita CA

- Cypress CA

- Covina CA

- Azusa CA

- Ceres CA

- Palm Springs CA

- San Luis Obispo CA

- San Jacinto CA

- Lincoln CA

- Newark CA

- Coachella CA

- Lompoc CA

- Danville town CA

- El Centro CA

- Bell Gardens CA

- San Bruno CA

- Rancho Palos Verdes CA

- Beaumont CA

- Rohnert Park CA

- Morgan Hill CA

- Brea CA

- Campbell CA

- La Puente CA

- San Gabriel CA

- La Quinta CA

- Calexico CA

- Culver City CA

- Oakley CA

- Pacifica CA

- Stanton CA

- Montclair CA

- Martinez CA

- Monrovia CA

- Los Banos CA

- Hollister CA

- Temple City CA

- San Juan Capistrano CA

- Bell CA

- Claremont CA

- West Hollywood CA

- Manhattan Beach CA

- Moorpark CA

- Wildomar CA

- Beverly Hills CA

- San Dimas CA

- Pleasant Hill CA

- Seaside CA

- Dana Point CA

- Lawndale CA

- Menlo Park CA

- Foster City CA

- Adelanto CA

- La Verne CA

- El Paso de Robles Paso Robles CA

- Saratoga CA

- Laguna Hills CA

- Goleta CA

- Banning CA

- Los Gatos town CA

- Santa Paula CA

- Burlingame CA

- Los Altos CA

- Walnut CA

- San Pablo CA

- San Carlos CA

- East Palo Alto CA

- Suisun City CA

- Atascadero CA

- Atwater CA

- Ridgecrest CA

- Monterey CA

- Desert Hot Springs CA

- Maywood CA

- Benicia CA

- Windsor town CA

- Imperial Beach CA

- Belmont CA

- Norco CA

- Eureka CA

- Lemon Grove CA

- Paradise town CA

- Wasco CA

- South Pasadena CA

- Twentynine Palms CA

- Brawley CA

- Lafayette CA

- Reedley CA

- Soledad CA

- Lemoore CA

- Hercules CA

- Coronado CA

- Galt CA

- Sanger CA

- Seal Beach CA

- El Cerrito CA

- San Fernando CA

- Calabasas CA

- Cudahy CA

- Selma CA

- Loma Linda CA

- Riverbank CA

- Dinuba CA

- Barstow CA

- Laguna Beach CA

- Corcoran CA

- Millbrae CA

- Port Hueneme CA

- Duarte CA

- Oakdale CA

- South Lake Tahoe CA

- Yucca Valley town CA

- Patterson CA

- Agoura Hills CA

- Marina CA

- Lomita CA

- La Canada Flintridge CA

- Arvin CA

- South El Monte CA

- American Canyon CA

- Lathrop CA

- Hermosa Beach CA

- Albany CA

- Blythe CA

- Dixon CA

- Pinole CA

- Orinda CA

- Chowchilla CA

- Rancho Mirage CA

- Arroyo Grande CA

- Arcata CA

- Shafter CA

- Santa Fe Springs CA

-

Colorado

- Denver CO

- Colorado Springs CO

- Aurora CO

- Fort Collins CO

- Lakewood CO

- Thornton CO

- Arvada CO

- Westminster CO

- Pueblo CO

- Centennial CO

- Boulder CO

- Greeley CO

- Longmont CO

- Loveland CO

- Broomfield CO

- Grand Junction CO

- Castle Rock town CO

- Commerce City CO

- Parker town CO

- Littleton CO

- Northglenn CO

- Brighton CO

- Englewood CO

- Wheat Ridge CO

- Fountain CO

- Lafayette CO

- Windsor town CO

- Erie town CO

- Evans CO

- Golden CO

- Louisville CO

- Montrose CO

- Durango CO

- Connecticut

- Delaware

- District of Columbia

-

Florida

- Jacksonville FL

- Miami FL

- Tampa FL

- Orlando FL

- St Petersburg FL

- Hialeah FL

- Tallahassee FL

- Fort Lauderdale FL

- Port St Lucie FL

- Cape Coral FL

- Pembroke Pines FL

- Hollywood FL

- Miramar FL

- Gainesville FL

- Coral Springs FL

- Miami Gardens FL

- Clearwater FL

- Pompano Beach FL

- Palm Bay FL

- West Palm Beach FL

- Lakeland FL

- Davie town FL

- Miami Beach FL

- Plantation FL

- Boca Raton FL

- Sunrise FL

- Deltona FL

- Palm Coast FL

- Largo FL

- Deerfield Beach FL

- Melbourne FL

- Boynton Beach FL

- Fort Myers FL

- Lauderhill FL

- Weston FL

- Kissimmee FL

- Homestead FL

- Delray Beach FL

- Tamarac FL

- Daytona Beach FL

- Wellington village FL

- North Miami FL

- Jupiter town FL

- North Port FL

- Port Orange FL

- Coconut Creek FL

- Ocala FL

- Sanford FL

- Margate FL

- Sarasota FL

- Doral FL

- Pensacola FL

- Bradenton FL

- Palm Beach Gardens FL

- Coral Gables FL

- Pinellas Park FL

- Bonita Springs FL

- Apopka FL

- Titusville FL

- Cutler Bay town FL

- Oakland Park FL

- North Miami Beach FL

- Fort Pierce FL

- North Lauderdale FL

- St Cloud FL

- Altamonte Springs FL

- Ocoee FL

- Greenacres FL

- Ormond Beach FL

- Hallandale Beach FL

- Winter Garden FL

- Oviedo FL

- Panama City FL

- Aventura FL

- Lake Worth FL

- Royal Palm Beach village FL

- Plant City FL

- Winter Haven FL

- Dunedin FL

- Cooper City FL

- Lauderdale Lakes FL

- Winter Springs FL

- Riviera Beach FL

- Dania Beach FL

- Miami Lakes town FL

- Clermont FL

- Winter Park FL

- DeLand FL

- Parkland FL

- Casselberry FL

- Rockledge FL

- Key West FL

- Temple Terrace FL

- Palmetto Bay village FL

- Tarpon Springs FL

- New Smyrna Beach FL

- Hialeah Gardens FL

- Sebastian FL

- Crestview FL

- Jacksonville Beach FL

- Haines City FL

- Sunny Isles Beach FL

- Venice FL

- Palm Springs village FL

- Fort Walton Beach FL

- Leesburg FL

- Edgewater FL

- Naples FL

- Sweetwater FL

- West Melbourne FL

- Lynn Haven FL

- DeBary FL

- Eustis FL

- Pinecrest village FL

- Bartow FL

- Belle Glade FL

- Seminole FL

- Punta Gorda FL

- Marco Island FL

-

Georgia

- Atlanta GA

- Columbus GA

- Augusta Richmond County GA

- Macon Bibb County GA

- Savannah GA

- Athens Clarke County GA

- Sandy Springs GA

- Roswell GA

- Johns Creek GA

- Albany GA

- Warner Robins GA

- Alpharetta GA

- Marietta GA

- Valdosta GA

- Smyrna GA

- Brookhaven GA

- Dunwoody GA

- Peachtree Corners GA

- Milton GA

- Gainesville GA

- Newnan GA

- Rome GA

- East Point GA

- Peachtree City GA

- Hinesville GA

- Dalton GA

- Douglasville GA

- Kennesaw GA

- LaGrange GA

- Statesboro GA

- Lawrenceville GA

- Duluth GA

- Woodstock GA

- Stockbridge GA

- Carrollton GA

- Canton GA

- Griffin GA

- McDonough GA

- Pooler GA

- Acworth GA

- Sugar Hill GA

- Union City GA

- Decatur GA

- Cartersville GA

- Snellville GA

- Milledgeville GA

- Forest Park GA

- Thomasville GA

- Suwanee GA

- St Marys GA

- Hawaii

- Idaho

-

Illinois

- Chicago IL

- Aurora IL

- Rockford IL

- Joliet IL

- Naperville IL

- Springfield IL

- Peoria IL

- Elgin IL

- Waukegan IL

- Champaign IL

- Cicero town IL

- Bloomington IL

- Arlington Heights village IL

- Evanston IL

- Schaumburg village IL

- Bolingbrook village IL

- Decatur IL

- Palatine village IL

- Skokie village IL

- Des Plaines IL

- Orland Park village IL

- Tinley Park village IL

- Oak Lawn village IL

- Berwyn IL

- Mount Prospect village IL

- Normal town IL

- Wheaton IL

- Hoffman Estates village IL

- Oak Park village IL

- Downers Grove village IL

- Glenview village IL

- Elmhurst IL

- DeKalb IL

- Lombard village IL

- Moline IL

- Belleville IL

- Plainfield village IL

- Urbana IL

- Buffalo Grove village IL

- Bartlett village IL

- Quincy IL

- Crystal Lake IL

- Carol Stream village IL

- Streamwood village IL

- Romeoville village IL

- Rock Island IL

- Hanover Park village IL

- Carpentersville village IL

- Wheeling village IL

- Park Ridge IL

- Addison village IL

- Calumet City IL

- Glendale Heights village IL

- Pekin IL

- Northbrook village IL

- St Charles IL

- Elk Grove Village village IL

- Woodridge village IL

- Oswego village IL

- Danville IL

- Galesburg IL

- Mundelein village IL

- Gurnee village IL

- Chicago Heights IL

- Algonquin village IL

- North Chicago IL

- Niles village IL

- Highland Park IL

- Burbank IL

- Granite City IL

- O Fallon IL

- Lake in the Hills village IL

- Lansing village IL

- Oak Forest IL

- Round Lake Beach village IL

- Glen Ellyn village IL

- West Chicago IL

- Wilmette village IL

- Alton IL

- Kankakee IL

- East St Louis IL

- McHenry IL

- Batavia IL

- Carbondale IL

- Vernon Hills village IL

- Huntley village IL

- Melrose Park village IL

- New Lenox village IL

- Harvey IL

- Belvidere IL

- Woodstock IL

- Lockport IL

- Westmont village IL

- Elmwood Park village IL

- Collinsville IL

- Freeport IL

- Edwardsville IL

- Homer Glen village IL

- Rolling Meadows IL

- Zion IL

- Maywood village IL

- Blue Island IL

- Loves Park IL

- Morton Grove village IL

- East Peoria IL

- Dolton village IL

- Machesney Park village IL

- Roselle village IL

- Lisle village IL

- Darien IL

- Bloomingdale village IL

- South Elgin village IL

- South Holland village IL

- Villa Park village IL

- Park Forest village IL

- Charleston IL

- Geneva IL

- East Moline IL

- Grayslake village IL

- Crest Hill IL

- Libertyville village IL

- Lake Zurich village IL

- Evergreen Park village IL

- Homewood village IL

- Mokena village IL

- Alsip village IL

- Lake Forest IL

- Montgomery village IL

- Jacksonville IL

- Matteson village IL

- Bellwood village IL

- Brookfield village IL

- Macomb IL

- Round Lake village IL

- Bourbonnais village IL

- Bensenville village IL

- Frankfort village IL

- Ottawa IL

- Franklin Park village IL

- Deerfield village IL

- Mattoon IL

- Yorkville IL

- Cary village IL

- Godfrey village IL

- Sycamore IL

- Palos Hills IL

- Hinsdale village IL

-

Indiana

- Indianapolis IN

- Fort Wayne IN

- Evansville IN

- South Bend IN

- Carmel IN

- Fishers town IN

- Bloomington IN

- Hammond IN

- Gary IN

- Lafayette IN

- Muncie IN

- Terre Haute IN

- Noblesville IN

- Kokomo IN

- Anderson IN

- Greenwood IN

- Elkhart IN

- Mishawaka IN

- Lawrence IN

- Jeffersonville IN

- Columbus IN

- Portage IN

- New Albany IN

- Richmond IN

- Merrillville town IN

- Westfield IN

- Valparaiso IN

- Goshen IN

- West Lafayette IN

- Michigan City IN

- Plainfield town IN

- Marion IN

- East Chicago IN

- Schererville town IN

- Hobart IN

- Crown Point IN

- Zionsville town IN

- Franklin IN

- Brownsburg town IN

- Highland town IN

- Munster town IN

- La Porte IN

- Clarksville town IN

- Greenfield IN

- Shelbyville IN

- Seymour IN

- Vincennes IN

- Logansport IN

- New Castle IN

-

Iowa

- Des Moines IA

- Cedar Rapids IA

- Davenport IA

- Sioux City IA

- Iowa City IA

- Waterloo IA

- West Des Moines IA

- Ames IA

- Council Bluffs IA

- Dubuque IA

- Ankeny IA

- Urbandale IA

- Cedar Falls IA

- Marion IA

- Bettendorf IA

- Marshalltown IA

- Mason City IA

- Clinton IA

- Burlington IA

- Ottumwa IA

- Fort Dodge IA

- Muscatine IA

- Johnston IA

- Coralville IA

- Waukee IA

- Kansas

-

Kentucky

- Louisville Jefferson County KY

- Lexington Fayette KY

- Bowling Green KY

- Owensboro KY

- Covington KY

- Richmond KY

- Hopkinsville KY

- Florence KY

- Georgetown KY

- Elizabethtown KY

- Nicholasville KY

- Henderson KY

- Frankfort KY

- Jeffersontown KY

- Independence KY

- Paducah KY

- Radcliff KY

- Ashland KY

- Madisonville KY

- Erlanger KY

- Murray KY

- Winchester KY

- St Matthews KY

- Louisiana

- Maine

- Manitoba

- Maryland

-

Massachusetts

- Boston MA

- Worcester MA

- Springfield MA

- Lowell MA

- Cambridge MA

- New Bedford MA

- Brockton MA

- Quincy MA

- Lynn MA

- Fall River MA

- Newton MA

- Somerville MA

- Lawrence MA

- Waltham MA

- Haverhill MA

- Malden MA

- Medford MA

- Taunton MA

- Chicopee MA

- Weymouth Town MA

- Revere MA

- Peabody MA

- Methuen MA

- Barnstable Town MA

- Everett MA

- Attleboro MA

- Pittsfield MA

- Salem MA

- Westfield MA

- Leominster MA

- Beverly MA

- Fitchburg MA

- Holyoke MA

- Marlborough MA

- Woburn MA

- Chelsea MA

- Braintree Town MA

- Watertown Town MA

- Franklin Town MA

- Gloucester MA

- Agawam Town MA

- West Springfield Town MA

- Northampton MA

- Melrose MA

- Gardner MA

- Winthrop Town MA

- Newburyport MA

-

Michigan

- Detroit MI

- Grand Rapids MI

- Warren MI

- Sterling Heights MI

- Ann Arbor MI

- Lansing MI

- Flint MI

- Dearborn MI

- Livonia MI

- Troy MI

- Westland MI

- Farmington Hills MI

- Kalamazoo MI

- Wyoming MI

- Rochester Hills MI

- Southfield MI

- Taylor MI

- St Clair Shores MI

- Pontiac MI

- Royal Oak MI

- Novi MI

- Dearborn Heights MI

- Battle Creek MI

- Kentwood MI

- Saginaw MI

- East Lansing MI

- Portage MI

- Roseville MI

- Midland MI

- Muskegon MI

- Lincoln Park MI

- Bay City MI

- Holland MI

- Jackson MI

- Eastpointe MI

- Madison Heights MI

- Oak Park MI

- Southgate MI

- Port Huron MI

- Burton MI

- Allen Park MI

- Garden City MI

- Mount Pleasant MI

- Wyandotte MI

- Inkster MI

- Walker MI

- Norton Shores MI

- Romulus MI

- Hamtramck MI

- Auburn Hills MI

- Marquette MI

- Adrian MI

- Birmingham MI

- Ferndale MI

- Monroe MI

- Ypsilanti MI

- Trenton MI

-

Minnesota

- Minneapolis MN

- St Paul MN

- Rochester MN

- Bloomington MN

- Duluth MN

- Brooklyn Park MN

- Plymouth MN

- Maple Grove MN

- Woodbury MN

- St Cloud MN

- Eagan MN

- Eden Prairie MN

- Coon Rapids MN

- Burnsville MN

- Blaine MN

- Lakeville MN

- Minnetonka MN

- Apple Valley MN

- Edina MN

- St Louis Park MN

- Mankato MN

- Maplewood MN

- Moorhead MN

- Shakopee MN

- Richfield MN

- Cottage Grove MN

- Roseville MN

- Inver Grove Heights MN

- Andover MN

- Brooklyn Center MN

- Savage MN

- Oakdale MN

- Fridley MN

- Winona MN

- Shoreview MN

- Owatonna MN

- Ramsey MN

- Prior Lake MN

- White Bear Lake MN

- Chanhassen MN

- Chaska MN

- Austin MN

- Champlin MN

- Elk River MN

- Faribault MN

- Rosemount MN

- Crystal MN

- Farmington MN

- Hastings MN

- New Brighton MN

- Lino Lakes MN

- Golden Valley MN

- New Hope MN

- South St Paul MN

- Northfield MN

- West St Paul MN

- Columbia Heights MN

- Willmar MN

- Forest Lake MN

- Stillwater MN

- Hopkins MN

- Albert Lea MN

- Mississippi

-

Missouri

- Kansas City MO

- St Louis MO

- Springfield MO

- Independence MO

- Columbia MO

- Lees Summit MO

- O Fallon MO

- St Joseph MO

- St Charles MO

- St Peters MO

- Blue Springs MO

- Florissant MO

- Joplin MO

- Chesterfield MO

- Jefferson City MO

- Cape Girardeau MO

- Wildwood MO

- University City MO

- Wentzville MO

- Ballwin MO

- Liberty MO

- Raytown MO

- Kirkwood MO

- Maryland Heights MO

- Gladstone MO

- Hazelwood MO

- Grandview MO

- Webster Groves MO

- Belton MO

- Sedalia MO

- Arnold MO

- Ferguson MO

- Nixa MO

- Warrensburg MO

- Raymore MO

- Rolla MO

- Ozark MO

- Manchester MO

- Farmington MO

- Hannibal MO

- Creve Coeur MO

- Kirksville MO

- Montana

- Nebraska

- Nevada

- New Brunswick

- New Hampshire

-

New Jersey

- Newark NJ

- Jersey City NJ

- Paterson NJ

- Elizabeth NJ

- Clifton NJ

- Trenton NJ

- Camden NJ

- Passaic NJ

- Union City NJ

- Bayonne NJ

- East Orange NJ

- Vineland NJ

- New Brunswick NJ

- Hoboken NJ

- West New York town NJ

- Perth Amboy NJ

- Plainfield NJ

- Sayreville borough NJ

- Hackensack NJ

- Kearny town NJ

- Linden NJ

- Atlantic City NJ

- Fort Lee borough NJ

- Fair Lawn borough NJ

- Garfield NJ

- Westfield town NJ

- Long Branch NJ

- Princeton NJ

- Rahway NJ

- Millville NJ

- Englewood NJ

- Bergenfield borough NJ

- Paramus borough NJ

- Cliffside Park borough NJ

- Ridgewood village NJ

- Bridgeton NJ

- Lodi borough NJ

- Carteret borough NJ

- South Plainfield borough NJ

- Summit NJ

- North Plainfield borough NJ

- Roselle borough NJ

- Palisades Park borough NJ

- Pleasantville NJ

- Elmwood Park borough NJ

- Morristown town NJ

- Hawthorne borough NJ

- Glassboro borough NJ

- Point Pleasant borough NJ

- Rutherford borough NJ

- Secaucus town NJ

- Dover town NJ

- Tinton Falls borough NJ

- Dumont borough NJ

- New Mexico

-

New York

- New York City NY

- Buffalo NY

- Rochester NY

- Yonkers NY

- Syracuse NY

- Albany NY

- New Rochelle NY

- Mount Vernon NY

- Schenectady NY

- Utica NY

- White Plains NY

- Hempstead village NY

- Troy NY

- Niagara Falls NY

- Binghamton NY

- Freeport village NY

- Valley Stream village NY

- Long Beach NY

- Rome NY

- Spring Valley village NY

- North Tonawanda NY

- Ithaca NY

- Poughkeepsie NY

- Jamestown NY

- Port Chester village NY

- Elmira NY

- Newburgh NY

- Harrison village NY

- Middletown NY

- Watertown NY

- Saratoga Springs NY

- Lindenhurst village NY

- Glen Cove NY

- Auburn NY

- Ossining village NY

- Rockville Centre village NY

- Peekskill NY

- Kingston NY

- Garden City village NY

- Kiryas Joel village NY

- Lockport NY

- Plattsburgh NY

- Lynbrook village NY

- Mamaroneck village NY

- Cortland NY

- Mineola village NY

- Amsterdam NY

- Oswego NY

- Lackawanna NY

- Scarsdale village NY

- Newfoundland And Labrador

-

North Carolina

- Charlotte NC

- Raleigh NC

- Greensboro NC

- Durham NC

- Winston Salem NC

- Fayetteville NC

- Cary town NC

- Wilmington NC

- High Point NC

- Greenville NC

- Asheville NC

- Concord NC

- Gastonia NC

- Jacksonville NC

- Chapel Hill town NC

- Rocky Mount NC

- Burlington NC

- Huntersville town NC

- Wilson NC

- Kannapolis NC

- Apex town NC

- Hickory NC

- Wake Forest town NC

- Indian Trail town NC

- Goldsboro NC

- Mooresville town NC

- Monroe NC

- Salisbury NC

- New Bern NC

- Holly Springs town NC

- Matthews town NC

- Sanford NC

- Garner town NC

- Cornelius town NC

- Thomasville NC

- Asheboro NC

- Statesville NC

- Mint Hill town NC

- Kernersville town NC

- Morrisville town NC

- Fuquay Varina town NC

- Lumberton NC

- Kinston NC

- Carrboro town NC

- Havelock NC

- Shelby NC

- Clemmons village NC

- Lexington NC

- Clayton town NC

- Boone town NC

- Elizabeth City NC

- Lenoir NC

- North Dakota

- Nova Scotia

-

Ohio

- Columbus OH

- Cleveland OH

- Cincinnati OH

- Toledo OH

- Akron OH

- Dayton OH

- Parma OH

- Canton OH

- Youngstown OH

- Lorain OH

- Hamilton OH

- Springfield OH

- Kettering OH

- Elyria OH

- Lakewood OH

- Cuyahoga Falls OH

- Middletown OH

- Euclid OH

- Newark OH

- Mentor OH

- Mansfield OH

- Beavercreek OH

- Cleveland Heights OH

- Strongsville OH

- Dublin OH

- Fairfield OH

- Findlay OH

- Warren OH

- Lancaster OH

- Grove City OH

- Lima OH

- Huber Heights OH

- Westerville OH

- Delaware OH

- Reynoldsburg OH

- Marion OH

- Stow OH

- Upper Arlington OH

- Brunswick OH

- Gahanna OH

- Fairborn OH

- Hilliard OH

- Westlake OH

- Massillon OH

- North Olmsted OH

- North Ridgeville OH

- Mason OH

- Bowling Green OH

- North Royalton OH

- Kent OH

- Garfield Heights OH

- Shaker Heights OH

- Wooster OH

- Medina OH

- Barberton OH

- Green OH

- Xenia OH

- Troy OH

- Zanesville OH

- Sandusky OH

- Riverside OH

- Trotwood OH

- Athens OH

- Centerville OH

- Avon Lake OH

- Solon OH

- Maple Heights OH

- Marysville OH

- Willoughby OH

- Hudson OH

- Avon OH

- Alliance OH

- Wadsworth OH

- South Euclid OH

- Oxford OH

- Chillicothe OH

- Perrysburg OH

- Sidney OH

- Piqua OH

- Lebanon OH

- Rocky River OH

- Parma Heights OH

- Portsmouth OH

- Ashland OH

- Oregon OH

- Miamisburg OH

- Painesville OH

- Pickerington OH

- Norwood OH

- Broadview Heights OH

- Berea OH

- Sylvania OH

- Brook Park OH

- Mayfield Heights OH

- Twinsburg OH

- Niles OH

- Forest Park OH

- Whitehall OH

- Ashtabula OH

- Eastlake OH

- Steubenville OH

- Springboro OH

- Tiffin OH

- Tallmadge OH

- North Canton OH

-

Oklahoma

- Oklahoma City OK

- Tulsa OK

- Norman OK

- Broken Arrow OK

- Lawton OK

- Edmond OK

- Moore OK

- Midwest City OK

- Enid OK

- Stillwater OK

- Muskogee OK

- Bartlesville OK

- Owasso OK

- Shawnee OK

- Yukon OK

- Ardmore OK

- Ponca City OK

- Bixby OK

- Duncan OK

- Del City OK

- Sapulpa OK

- Jenks OK

- Mustang OK

- Bethany OK

- Sand Springs OK

- Altus OK

- Claremore OK

- McAlester OK

- El Reno OK

-

Ontario

- Toronto ON

- Ottawa ON

- Hamilton ON

- Kitchener ON

- London ON

- St Catharines ON

- Oshawa ON

- Windsor ON

- Barrie ON

- Guelph ON

- Kingston ON

- Sudbury ON

- Thunder Bay ON

- Kanata ON

- Brantford ON

- Peterborough ON

- Sarnia ON

- Milton ON

- Sault Ste Marie ON

- Belleville ON

- North Bay ON

- Cornwall ON

- Chatham ON

- Whitchurch Stouffville ON

- St Thomas ON

- Georgetown ON

- Woodstock ON

- Midland ON

- Leamington ON

- Stratford ON

- Orangeville ON

- Timmins ON

- Orillia ON

- Bolton ON

- Keswick Elmhurst Beach ON

- Stouffville ON

- Georgina ON

- Niagara Falls ON

- Cambridge ON

- Brampton ON

- Burlington ON

- Concord ON

- East york ON

- Etobicoke ON

- Malton ON

- Markham ON

- Mississauga ON

- North York ON

- Oakville ON

- Richmond Hill ON

- Scarborough ON

- Thornhill ON

- Vaughan ON

- Woodbridge ON

- Ajax ON

- Aurora ON

- Newmarket ON

- Pickering ON

- Stoney Creek ON

- Waterloo ON

- Whitby ON

- Dufferin County ON

- Simcoe County ON

- Dundas ON

- Nestleton ON

- Nobleton ON

- Port Union ON

- Rexdale ON

- Schomberg ON

- Steeles ON

- York ON

- Yorkdale ON

- Yorkville ON

- ChurchVille ON

- Downsview ON

- Smithfield ON

- Bramlea ON

- Clarington ON

- Orono ON

- Brock ON

- Scugog ON

- Halton Hills ON

- Caledon ON

- Alton ON

- Erin Mills ON

- palgrave ON

- Port Credit ON

- Streetsville ON

- Cooksville ON

- East Gwillimbury ON

- King ON

- Unionville ON

- Mono ON

- Bradford West Gwillimbury ON

- Niagara ON

- Newcastle ON

- Bowmanville ON

- Saint Thomas ON

- Brockville ON

- Bradford ON

- Owen Sound ON

- Valley East ON

- Lindsay ON

- Fergus ON

- Cobourg ON

- Collingwood ON

- Pembroke ON

- Fort Erie ON

- Alliston ON

- Tillsonburg ON

- Simcoe ON

- Strathroy ON

- Amherstburg ON

- Petawawa ON

- Port Hope ON

- Ingersoll ON

- New Hamburg ON

- Paris ON

- Uxbridge ON

- Kenora ON

- Elliot Lake ON

- Rockland ON

- Wasaga Beach ON

- Beamsville ON

- Hawkesbury ON

- Wallaceburg ON

- Arnprior ON

- Carleton Place ON

- Caledonia ON

- Haileybury ON

- Elmira ON

- Acton ON

- Smiths Falls ON

- Port Perry ON

- Bracebridge ON

- Renfrew ON

- Fort Frances ON

- Kapuskasing ON

- Port Elgin ON

- Goderich ON

- Hanover ON

- Crystal Beach ON

- Kirkland Lake ON

- Aylmer ON

- Napanee ON

- Huntsville ON

- Porcupine ON

- Essex ON

- Lively ON

- Listowel ON

- Kincardine ON

- Sturgeon Falls ON

- St Marys ON

- Port Dover ON

- Embrun ON

- Dryden ON

- Perth ON

- Parry Sound ON

- Sutton ON

- Brighton ON

- Gravenhurst ON

- Shelburne ON

- Dunnville ON

- Petrolia ON

- Gananoque ON

-

Oregon

- Portland OR

- Salem OR

- Eugene OR

- Gresham OR

- Hillsboro OR

- Beaverton OR

- Bend OR

- Medford OR

- Springfield OR

- Corvallis OR

- Albany OR

- Tigard OR

- Lake Oswego OR

- Keizer OR

- Grants Pass OR

- Oregon City OR

- McMinnville OR

- Redmond OR

- Tualatin OR

- West Linn OR

- Woodburn OR

- Forest Grove OR

- Newberg OR

- Wilsonville OR

- Roseburg OR

- Klamath Falls OR

- Ashland OR

- Milwaukie OR

- Sherwood OR

- Central Point OR

-

Pennsylvania

- Philadelphia PA

- Pittsburgh PA

- Allentown PA

- Erie PA

- Reading PA

- Scranton PA

- Bethlehem PA

- Lancaster PA

- Harrisburg PA

- Altoona PA

- York PA

- State College borough PA

- Wilkes Barre PA

- Norristown borough PA

- Chester PA

- Bethel Park muni PA

- Williamsport PA

- Monroeville muni PA

- Plum borough PA

- Easton PA

- Lebanon PA

- Hazleton PA

- Pottstown borough PA

- New Castle PA

- Chambersburg borough PA

- Johnstown PA

- West Mifflin borough PA

- Murrysville muni PA

- Baldwin borough PA

- McKeesport PA

- West Chester borough PA

- Carlisle borough PA

- Prince Edward Island

-

Quebec

- Montreal QC

- Quebec City QC

- Sherbrooke QC

- Trois Rivisres QC

- Chicoutimi QC

- Saint Jean sur Richelieu QC

- Chateauguay QC

- Drummondville QC

- Saint Jerome QC

- Granby QC

- Beloeil QC

- Saint Hyacinthe QC

- Shawinigan QC

- Joliette QC

- Victoriaville QC

- Salaberry de Valleyfield QC

- Rimouski QC

- Sorel Tracy QC

- Alma QC

- Saint Georges QC

- Val dOr QC

- Rouyn Noranda QC

- Buckingham QC

- Gatineau QC

- Jonquisre QC

- Rhode Island

- Saskatchewan

-

South Carolina

- Columbia SC

- Charleston SC

- North Charleston SC

- Mount Pleasant town SC

- Rock Hill SC

- Greenville SC

- Summerville town SC

- Sumter SC

- Goose Creek SC

- Hilton Head Island town SC

- Florence SC

- Spartanburg SC

- Aiken SC

- Myrtle Beach SC

- Greer SC

- Anderson SC

- Mauldin SC

- Greenwood SC

- North Augusta SC

- Easley SC

- Conway SC

- Simpsonville SC

- Lexington town SC

- Hanahan SC

- South Dakota

-

Tennessee

- Memphis TN

- Nashville Davidson TN

- Knoxville TN

- Chattanooga TN

- Clarksville TN

- Murfreesboro TN

- Franklin TN

- Jackson TN

- Johnson City TN

- Bartlett TN

- Hendersonville TN

- Kingsport TN

- Collierville town TN

- Smyrna town TN

- Cleveland TN

- Brentwood TN

- Germantown TN

- Columbia TN

- La Vergne TN

- Spring Hill TN

- Gallatin TN

- Cookeville TN

- Lebanon TN

- Mount Juliet TN

- Morristown TN

- Oak Ridge TN

- Maryville TN

- Bristol TN

- Farragut town TN

- East Ridge TN

- Shelbyville TN

- Tullahoma TN

-

Texas

- Houston TX

- San Antonio TX

- Dallas TX

- Austin TX

- Fort Worth TX

- El Paso TX

- Arlington TX

- Corpus Christi TX

- Plano TX

- Laredo TX

- Lubbock TX

- Garland TX

- Irving TX

- Amarillo TX

- Grand Prairie TX

- Brownsville TX

- McKinney TX

- Pasadena TX

- Frisco TX

- Mesquite TX

- McAllen TX

- Killeen TX

- Waco TX

- Carrollton TX

- Denton TX

- Midland TX

- Abilene TX

- Beaumont TX

- Odessa TX

- Round Rock TX

- Richardson TX

- Wichita Falls TX

- College Station TX

- Pearland TX

- Lewisville TX

- Tyler TX

- San Angelo TX

- League City TX

- Allen TX

- Sugar Land TX

- Edinburg TX

- Mission TX

- Longview TX

- Bryan TX

- Baytown TX

- Pharr TX

- Missouri City TX

- Temple TX

- Flower Mound town TX

- North Richland Hills TX

- New Braunfels TX

- Victoria TX

- Harlingen TX

- Conroe TX

- Cedar Park TX

- Mansfield TX

- Georgetown TX

- San Marcos TX

- Rowlett TX

- Pflugerville TX

- Port Arthur TX

- Euless TX

- DeSoto TX

- Grapevine TX

- Galveston TX

- Bedford TX

- Cedar Hill TX

- Texas City TX

- Wylie TX

- Keller TX

- Haltom City TX

- Burleson TX

- Rockwall TX

- The Colony TX

- Coppell TX

- Huntsville TX

- Sherman TX

- Duncanville TX

- Hurst TX

- Lancaster TX

- Friendswood TX

- Weslaco TX

- Texarkana TX

- Schertz TX

- San Juan TX

- Lufkin TX

- Del Rio TX

- Little Elm TX

- La Porte TX

- Rosenberg TX

- Leander TX

- Deer Park TX

- Nacogdoches TX

- Copperas Cove TX

- Socorro TX

- Kyle TX

- Farmers Branch TX

- Waxahachie TX

- Cleburne TX

- Southlake TX

- Harker Heights TX

- Big Spring TX

- Eagle Pass TX

- Weatherford TX

- Lake Jackson TX

- Seguin TX

- Kingsville TX

- Greenville TX

- Alvin TX

- Cibolo TX

- Balch Springs TX

- Colleyville TX

- Paris TX

- Marshall TX

- San Benito TX

- University Park TX

- Watauga TX

- Corsicana TX

- Sachse TX

- Denison TX

- Kerrville TX

- Benbrook TX

- Saginaw TX

- Hutto TX

- Plainview TX

- Converse TX

- Midlothian TX

- Corinth TX

- Murphy TX

- Belton TX

- Universal City TX

- Dickinson TX

- Angleton TX

- Alice TX

- Stephenville TX

- Horizon City TX

- Alamo TX

- Brownwood TX

- Orange TX

- Ennis TX

- Pampa TX

- Palestine TX

- Stafford TX

- Bellaire TX

- Forney TX

- South Houston TX

-

Utah

- Salt Lake City UT

- West Valley City UT

- Provo UT

- West Jordan UT

- Orem UT

- Sandy UT

- Ogden UT

- St George UT

- Layton UT

- South Jordan UT

- Taylorsville UT

- Lehi UT

- Logan UT

- Murray UT

- Draper UT

- Bountiful UT

- Riverton UT

- Roy UT

- Spanish Fork UT

- Pleasant Grove UT

- Cottonwood Heights UT

- Tooele UT

- Midvale UT

- Springville UT

- Clearfield UT

- Kaysville UT

- Cedar City UT

- Herriman UT

- American Fork UT

- Holladay UT

- Syracuse UT

- Eagle Mountain UT

- South Salt Lake UT

- Saratoga Springs UT

- Washington UT

- Farmington UT

- Clinton UT

- Payson UT

- North Salt Lake UT

- Brigham City UT

- North Ogden UT

- Highland UT

- Vermont

-

Virginia

- Virginia Beach VA

- Norfolk VA

- Chesapeake VA

- Richmond VA

- Newport News VA

- Alexandria VA

- Hampton VA

- Roanoke VA

- Portsmouth VA

- Suffolk VA

- Lynchburg VA

- Harrisonburg VA

- Leesburg town VA

- Charlottesville VA

- Blacksburg town VA

- Danville VA

- Manassas VA

- Petersburg VA

- Fredericksburg VA

- Winchester VA

- Salem VA

- Herndon town VA

- Staunton VA

- Fairfax VA

- Hopewell VA

- Christiansburg town VA

- Waynesboro VA

- Colonial Heights VA

- Radford VA

-

Washington

- Seattle WA

- Spokane WA

- Tacoma WA

- Vancouver WA

- Bellevue WA

- Kent WA

- Everett WA

- Renton WA

- Federal Way WA

- Yakima WA

- Spokane Valley WA

- Kirkland WA

- Bellingham WA

- Kennewick WA

- Auburn WA

- Pasco WA

- Marysville WA

- Lakewood WA

- Redmond WA

- Shoreline WA

- Richland WA

- Sammamish WA

- Burien WA

- Olympia WA

- Lacey WA

- Edmonds WA

- Puyallup WA

- Bremerton WA

- Lynnwood WA

- Bothell WA

- Longview WA

- Issaquah WA

- Wenatchee WA

- Mount Vernon WA

- University Place WA

- Walla Walla WA

- Pullman WA

- Des Moines WA

- Lake Stevens WA

- SeaTac WA

- Maple Valley WA

- Mercer Island WA

- Bainbridge Island WA

- Oak Harbor WA

- Kenmore WA

- Moses Lake WA

- Camas WA

- Mukilteo WA

- Mountlake Terrace WA

- Tukwila WA

- Port Angeles WA

- Mill Creek WA

- Covington WA

- Battle Ground WA

- Tumwater WA

- Bonney Lake WA

- Arlington WA

- Ellensburg WA

- Monroe WA

- West Virginia

-

Wisconsin

- Milwaukee WI

- Madison WI

- Green Bay WI

- Kenosha WI

- Racine WI

- Appleton WI

- Waukesha WI

- Eau Claire WI

- Oshkosh WI

- Janesville WI

- West Allis WI

- La Crosse WI

- Sheboygan WI

- Wauwatosa WI

- Fond du Lac WI

- New Berlin WI

- Wausau WI

- Brookfield WI

- Greenfield WI

- Beloit WI

- Franklin WI

- Menomonee Falls village WI

- Oak Creek WI

- Manitowoc WI

- Sun Prairie WI

- West Bend WI

- Fitchburg WI

- Superior WI

- Stevens Point WI

- Mount Pleasant village WI

- Neenah WI

- Caledonia village WI

- Muskego WI

- De Pere WI

- Watertown WI

- Mequon WI

- South Milwaukee WI

- Pleasant Prairie village WI

- Germantown village WI

- Howard village WI

- Marshfield WI

- Middleton WI

- Onalaska WI

- Cudahy WI

- Wisconsin Rapids WI

- Menasha WI

- Wyoming

We Expertise in

Custom Molded Products

Rubber To Metal Bonding

Silicone To Metal Bonding

Injection and Compression Rubber Mouldings

Custom Bellows

Grommets

Diaphrams

Rubber Mounts

Custom Seals and Gaskets